Add or Modify an Insulated Concrete Form Wall Assembly

|

|

|

|

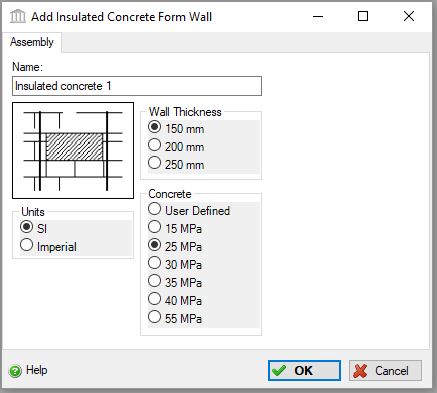

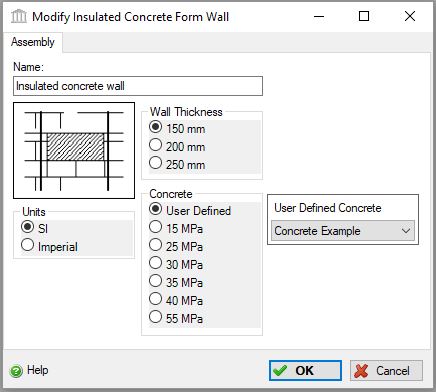

This dialog can be used to:

- define and add a "insulated concrete form wall" sub-assembly to a "Custom Wall" assembly in the project, or

- modify or view "insulated concrete form wall" sub-assembly to a "Custom Wall" assembly in the project.

| Description / Assumptions / Limits | Required inputs |

|---|---|

Insulated Concrete Form

|

|

Benchmark Concretes (selected with radio buttons) Note:

The Canadian and American ready mix associations, CRMCA and NRMCA, have published EPDs with multiple mix designs, those mix designs are available to import into users’ User Defined Concrete Mix Design Libraries, for instructions on how to do this download the PDF file at File>Bulk Product Projects.

Six benchmark designs are available in each concrete assembly as radio button choices ranging from 15-55 MPa, 2500-8000 psi. When a user chooses one of these benchmark mixes for an assembly for project locations in Canada, the CRMCA mix will be added to the bill of materials, and for projects in US locations, the NRMCA mix will be added. The NRMCA EPD included a 2500 psi (15 MPa) benchmark mix, but the CRMCA’s EPD did not include a 15 MPa mix. Therefore, the mix design for “Concrete Benchmark CAN 15 MPa” is in fact the mix design from the NRMCA EPD and cannot be found in the CRMCA EPD.

Remember that these mix designs only define the amounts of each individual material in each mix, the LCA effects for each of those materials are calculated with material data according to the project location. In other words, the Canadian 15 MPa concrete copies an NRMCA mix design, but uses Canadian data for Portland cement, aggregates, etc.

There are six NRMCA benchmark mixes and eight CRMCA benchmarks. The CRMCA 45, 50 and 60 MPa benchmarks are not available to choose from in the assembly dialogs, but they are included in the database. If you wish to use one of these benchmarks in your assembly, you can choose them as user defined products, but in order to do that, you must create them as user defined products. To do this, go to Tools> User Defined Concrete Mix Design Library, check the Include Database Products box at the top of the form, and the database products will appear in grey. Click the product you want, then click Duplicate, and a copy will be created. We recommend you rename this duplicate so that you can distinguish it from the database version. This is now a User Defined copy of the database mix and will be available in the User Defined drop down box of each concrete assembly form. All mixes, database and user defined are available in Extra Basic Materials.

The CRMCA EPD report is available at https://www.crmca.ca/s/CRMCA-EPD-20170317.pdf

The NRMCA EPD report is available at https://www.nrmca.org/sustainability/EPDProgram/Index.asp#IndustryWideEPD

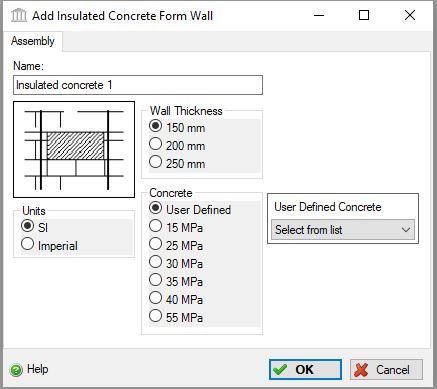

User Defined Concrete Mix Design Note:

When "User Defined" is selected from the "Concrete" options, the "Concrete Flyash" list is disabled and a selection box listing all of the entries in the "User Defined Concrete Mix Design Library" is enabled. In order to edit the "User Defined Concrete Mix Design Library", you will need to launch the "User Defined Concrete Mix Design Library" dialog from the "Tools" menu.

Seismic Note:

Seismic adjustments include extra rebar.

Cautionary Note:

The flyash concentration levels as provided should be treated as indicators only of employing more or less flyash in a typical mix. The results for different regions of N. America may be quite different and local conditions, availability and design mixes should be consulted.

Field Descriptions:

- Name:

- Enter a name for this assembly. All assemblies within a project must be uniquely named within each assembly group. Names maybe alphanumeric (e.g., foundation 1).

Units:- Here you can set the units of measure as either "SI" or "Imperial". Changing the default units here affects only the current assembly but will not override the Default Units of Measure nor the Units of Measure settings for open projects or any other assemblies within open projects.

Thickness:- Click a radio button to select the thickness of the concrete wall to be used in this assembly. The width, length and thickness geometry fields are used to calculate the volume of concrete used in the assembly.

- 150 mm (6 in)

- 200 mm (8 in)

- 250 mm (10 in)

Rebar:- Click a radio button to select a reinforcement bar size from the three sizes provided for use in the assembly (Metric Sizes: #10 M, #15 M and #20 M or Imperial Sizes: #4, #5, or #6)

- #10 M (#4 Imperial)

- #15 M (#5 Imperial)

- #20 M (#6 Imperial)

Concrete:- Click a radio button to select the concrete strength class:

- Concrete 20 MPa (m3) or 3000 psi (cubic yards) with flyash concentrations of average (9%) or 25% or 35% cement replacement.

- Concrete 30 MPa (m3) or 4000 psi (cubic yards) with flyash concentrations of average (9%) or 25% or 35% cement replacement.

- Concrete 60 MPa (m3) or 9000 psi (cubic yards) with silica fume concentrations of 10%. No flyash (silica fume) variations are provided for this design mix.

Concrete Flyash %:- Click a radio button to select the percentage concentration of flyash cement replacement to be used in this assembly - see the cautionary note above.:

- average (9%)

- 25%

- 35%

Help Button:- Click the "Help" button to open the Help pop-up window.

OK Button- Click the "OK" button to accept and save the current assembly settings and close this dialog.

Cancel Button- Click the "Cancel" button to discard the current assembly settings and close this dialog.

Notes:-

- Length:

- The length is inherited from the "Custom Wall" assembly to which this wall "component" sub-assembly belongs.

Height:- The height is inherited from the "Custom Wall" assembly to which this wall "component" sub-assembly belongs.

Openings:- Openings are not captured for this "component" wall assembly. Rather, openings are defined for the the "Custom Wall" assembly to which this wall "component" sub-assembly belongs.

Envelope:- Envelope information is not captured for this "component" wall assembly. Rather, openings are defined for the the "Custom Wall" assembly to which this wall "component" sub-assembly belongs.

Duplicate:- This wall "component" sub-assembly can only be duplicated using the "Duplicate" button available in the "Add or Modify Custom Wall" assembly dialog.

Delete:- This wall "component" sub-assembly can only be deleted using the "Delete" button available in the "Add or Modify Custom Wall" assembly dialog.