Add or Modify a Composite Metal Floor

|

|

|

|

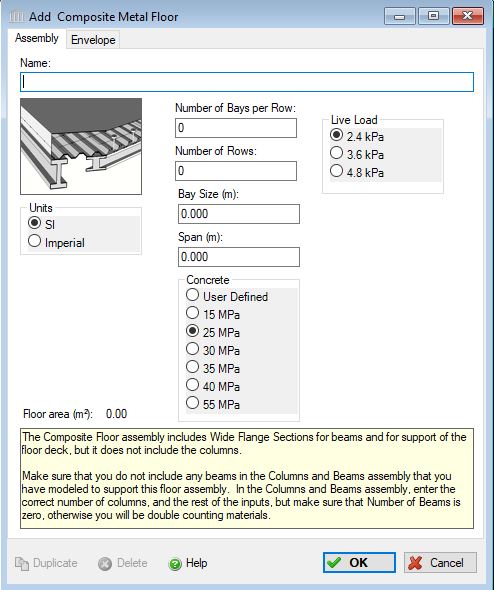

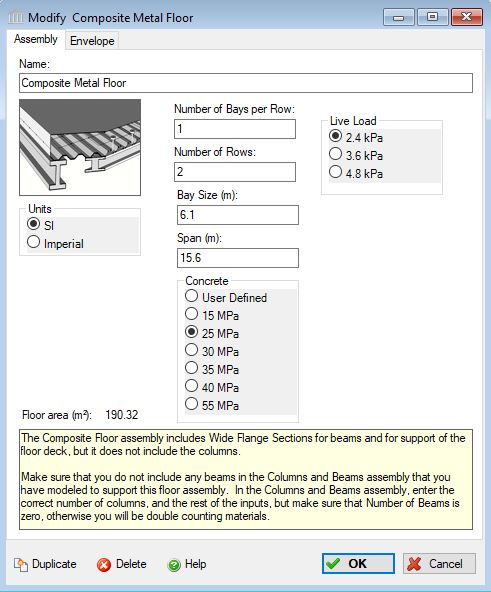

This dialog can be used to:

- define and add a "composite metal floor " assembly to a project, or

- modify or view "composite metal floor" assembly that has been added to a project.

- define an envelope for this assembly.

| Description / Assumptions / Limits | Required inputs |

|---|---|

Composite Metal floor

|

|

Terminology:

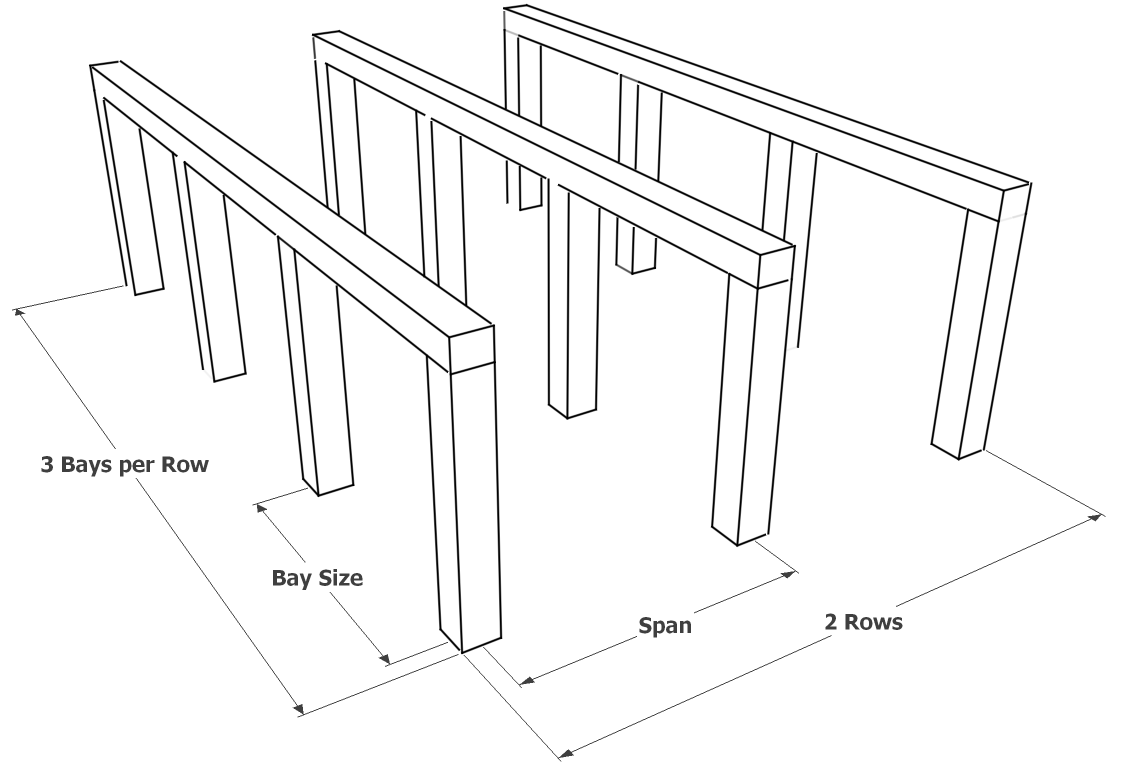

There is sometimes confusion about different terminology for different structural elements. This software refers to the Bay Size as the length of a beam supported by two columns, and Span as the distance between adjacent, parallel beams (see figure below). The Composite Floor assembly includes the material quantities for wide flange girders (what this tool would call beams) that are supported by columns, and those girders will support wide flange beams, perpendicular to the girders, that support the steel and concrete deck. In short, Bay Size is the length of the girders, and Span is the length of the beams.

Bay Size and Span will determine the area of one bay, a row is a row of bays, NOT a row of girders. The drawing below shows two rows of bays, and each row is three bays long. The total floor area in the example below is (Bay Size x Span) x Number of Bays per Row x Number of Rows (Bay Size x Span x 6).

Benchmark Concretes (selected with radio buttons) Note:

The Canadian and American ready mix associations, CRMCA and NRMCA, have published EPDs with multiple mix designs, those mix designs are available to import into users’ User Defined Concrete Mix Design Libraries, for instructions on how to do this download the PDF file at File>Bulk Product Projects.

Six benchmark designs are available in each concrete assembly as radio button choices ranging from 15-55 MPa, 2500-8000 psi. When a user chooses one of these benchmark mixes for an assembly for project locations in Canada, the CRMCA mix will be added to the bill of materials, and for projects in US locations, the NRMCA mix will be added. The NRMCA EPD included a 2500 psi (15 MPa) benchmark mix, but the CRMCA’s EPD did not include a 15 MPa mix. Therefore, the mix design for “Concrete Benchmark CAN 15 MPa” is in fact the mix design from the NRMCA EPD and cannot be found in the CRMCA EPD.

Remember that these mix designs only define the amounts of each individual material in each mix, the LCA effects for each of those materials are calculated with material data according to the project location. In other words, the Canadian 15 MPa concrete copies an NRMCA mix design, but uses Canadian data for Portland cement, aggregates, etc.

There are six NRMCA benchmark mixes and eight CRMCA benchmarks. The CRMCA 45, 50 and 60 MPa benchmarks are not available to choose from in the assembly dialogs, but they are included in the database. If you wish to use one of these benchmarks in your assembly, you can choose them as user defined products, but in order to do that, you must create them as user defined products. To do this, go to Tools> User Defined Concrete Mix Design Library, check the Include Database Products box at the top of the form, and the database products will appear in grey. Click the product you want, then click Duplicate, and a copy will be created. We recommend you rename this duplicate so that you can distinguish it from the database version. This is now a User Defined copy of the database mix and will be available in the User Defined drop down box of each concrete assembly form. All mixes, database and user defined are available in Extra Basic Materials.

The CRMCA EPD report is available at https://www.crmca.ca/s/CRMCA-EPD-20170317.pdf

The NRMCA EPD report is available at https://www.nrmca.org/sustainability/EPDProgram/Index.asp#IndustryWideEPD

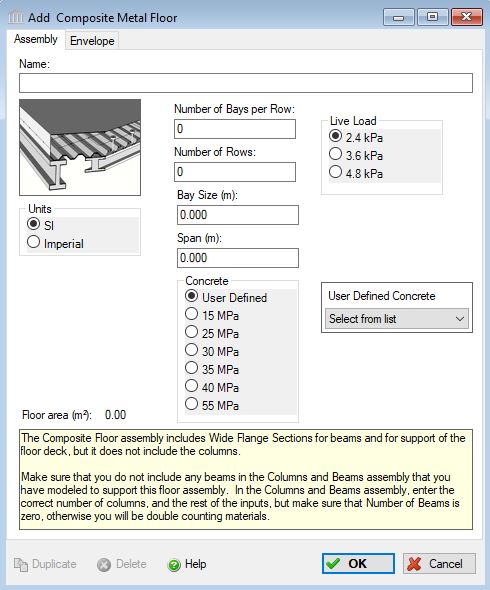

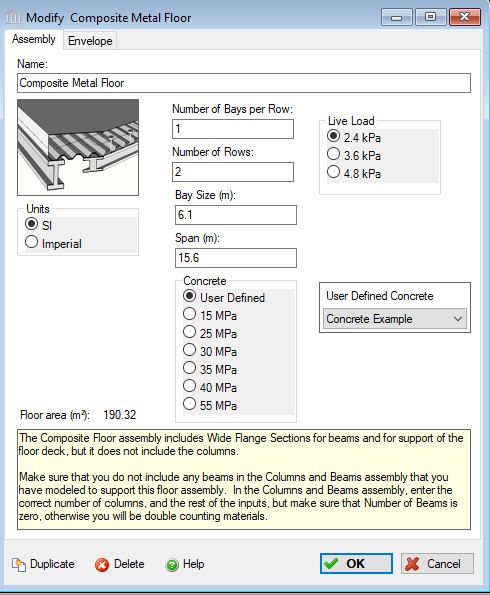

User Defined Concrete Mix Design Note:

When "User Defined" is selected from the "Concrete" options, the "Concrete Flyash" list is disabled and a selection box listing all of the entries in the "User Defined Concrete Mix Design Library" is enabled. In order to edit the "User Defined Concrete Mix Design Library", you will need to launch the "User Defined Concrete Mix Design Library" dialog from the "Tools" menu.

Seismic Note:

For seismically active regions, Steel Wire Mesh is replaced by Rebar .

Cautionary Note:

The Composite Floor assembly includes Wide Flange Sections for beams and for support of the floor deck, but it does not include the columns.

Make sure that you do not include any beams in the Columns and Beams assembly that you have modeled to support this floor assembly.

In the Columns and Beams assembly, enter the correct number of columns, and the rest of the inputs, but make sure that Number of Beams is zero, otherwise you will be double counting materials.

Cautionary Note:

The flyash concentration levels as provided should be treated as indicators only of employing more or less flyash in a typical mix. The results for different regions of N. America may be quite different and local conditions, availability and design mixes should be consulted.

Field Descriptions:

- Name:

- Enter a name for this assembly. All assemblies within a project must be uniquely named within each assembly group. Names maybe alphanumeric (e.g., floor 1).

Number of Bays per Row :- Enter the total number of bays per row (see figure above).

Number of Rows :- Enter the total number of rows (see figure above).

Bay Size:- Enter the bay size (i.e. the distance between columns supporting each girder)

Span:- Enter the span (i.e. the the distance between adjacent parallel girders.

Concrete:- Click a radio button to select the desired concrete strength class.

- Concrete 20 MPa (m3) or 3000 psi (cubic yards) with flyash concentrations of average (9%) or 25% or 35% cement replacement.

- Concrete 30 MPa (m3) or 4000 psi (cubic yards) with flyash concentrations of average (9%) or 25% or 35% cement replacement.

- Concrete 60 MPa (m3) or 9000 psi (cubic yards) with silica fume concentrations of 10%. No flyash (silica fume) variations are provided for this design mix.

- User Defined Concrete Mix Design

Concrete Flyash %:- Click a radio button to select the percentage concentration of flyash cement replacement to be used in this assembly - see the cautionary note above.:

- average (9%)

- 25%

- 35%

Live Load:- Click a radio button to select the live load to be carried by this column and beam assembly system.

- 2.4 kPa (50 psf) represents a typical roof load for a typical office / residential occupancy condition (above the first floor)

- 3.6 kPa (75 psf) represents a typical mechanical/service room loading

- 4.8 kPa (100 psf) would be indicative of heavier floor loads such as assembly areas, balconies/mezzanines, corridors, lobbies/exit areas and storage areas.

Units:- Here you can set the units of measure as either "SI" or "Imperial". Changing the default units here affects only the current assembly but will not override the Default Units of Measure nor the Units of Measure settings for open projects or any other assemblies within open projects.

Floor Area (m2 or ft2) Note:- As a user friendly check, the total floor area calculated by the application (as per the users input) is reported in the bottom left hand corner of the dialog box.

Duplicate Button- Click the "Duplicate" button to create an exact duplicate of the current assembly. The duplicate assembly will be added to the current project. This button is only available when editing or viewing an assembly that has already been saved in the current project.

Delete Button- Click the "Delete" button to delete the current assembly from the current project. This button is only available when editing or viewing an assembly that has already been saved in the current project.

Help Button:- Click the "Help" button to open the Help pop-up window.

OK Button- Click the "OK" button to accept and save the current assembly settings and close this dialog.

Cancel Button- Click the "Cancel" button to discard the current assembly settings and close this dialog.