Bulk Product Projects

Selecting this "Bulk Product Projects" option from the File Menu allows the user to open one or more project files from the Bulk Product Projects library folder. These files enable users to bulk add a list of previously defined concrete mix "recipes" to the User Defined Concrete Mix Design Library and subsequently be re-used.

Benchmark and EPD Mix Designs Available in the Impact Estimator for Buildings (IE4B) v5.5

Overview

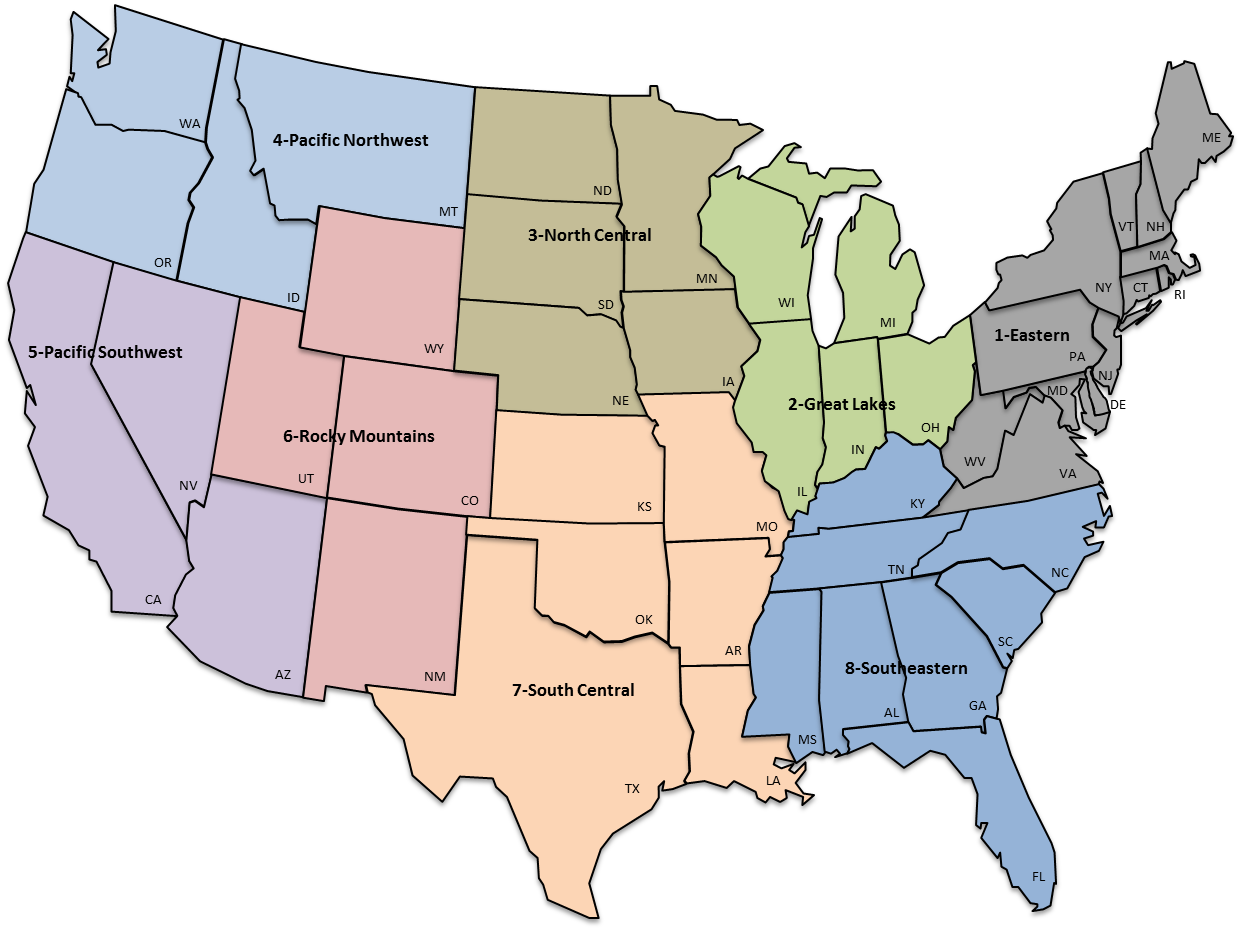

The NRMCA, National Ready Mix Concrete Association, updated its Industry Wide cradle to gate life cycle analysis (LCA) and environmental product declarations (EPD) for ready mixed concrete in 2016 (version 2), adding data from additional ready mix plants that contributed data to its 2014 LCA/EPD (version 1). Accompanying the LCA/EPD is a regional benchmark, or industry averages report, that calculates the environmental effects for typical mix designs in each of NRMCA’s eight geographical regions and on a national basis, using the same life cycle inventory as the LCA/EPD.

As part of the Benchmark and EPD reports, the NRMCA has provided users with the mix designs from those reports to users of the IE4B to save them from having to recreate those mix designs themselves in the IE4B User Defined Concrete Mix Design Library (under the Tools menu). This has been done by providing Athena project files (.AT4) in the Bulk Product Projects folder under the File menu, that users can open in the IE4B, and the mix designs will be added to their library, ready to use in project models.

In 2021, the NRMCA updated it’s industry wide EPDs (version 3) and many (if not all) of the EPD and benchmark mixes changed. The new mixes have been updated in v5.5.

Similarly, in 2017, the Canadian Ready Mix Concrete Association, CRMCA, published an Industry Wide EPD, and starting in v5.3, those mixes are available in the IE4B in the Bulk Product Projects folder. The CRMCA EPD is available at https://www.crmca.ca/s/CRMCA-EPD-20170317.pdf and the full LCA report is available at http://www.athenasmi.org/wp-content/uploads/2017/06/CRMCA_LCA_Project_Report_20161201.pdf

The CRMCA has also updated it’s EPDs, but the underlying LCA report did not make public the mix designs, and it also did its analysis on mix designs for each region across Canada, as opposed to average national mixes. This has resulted in it being untenable to provide all those new mixes on the IE4B. The mixes provided in Bulk Product Projects are the same as previous versions as described below, and can be used as generally representative mixes for each category, but they do not match the mixes used in the most recent regional EPDs.

Although outdated and probably obsolete to the vast majority of users, we still include this reference to v5.2 mixes for completeness’ sake. Previous to v5.2 of the IE4B, users may have loaded mix designs into their library with a similar project file that contained the 48 EPD v1 mix designs, and may still have those designs in your library and have used them in projects. If that is the case, be sure to read the bottom of this document to see how the new mixes will affect your previous projects (not much if any).

The previous 48 mixes were provided in one project file and you had no choice but load all 48 if you wanted to use any of the mixes. This ended up being a little cumbersome because every time you wanted to choose a concrete mix, a long list of 48 appeared and it was difficult to sift through them all to find the one you wanted. Also, with v2 of the EPD and Benchmark reports, we are now providing over 150 mixes, many more than any one user could possibly want to use, so we’ve regionally compartmentalized the mixes in several files with 9-12 mixes in each, to allow users to pick just the ones that apply to them and make the whole exercise easier to manage.

Just to emphasize, these mix design files merely provide the mix designs (the proportions of each component material) so users don’t need to copy them themselves manually from the Benchmark and LCA/EPD reports, the results will still depend on the underlying data for each component material (and changes to that data, and your chosen project location. A mix labeled “Eastern”, for NRMCA’s Eastern region can be used in any IE4B location, it just means that this is a typical mix design used in the Eastern region. If an Eastern mix is used in a Vancouver project location, then the manufacturing energy use will be calculated using Vancouver’s energy grid profile. Any changes to a material component’s LCA data (e.g. the Portland cement data for both Canada and the US has been updated in v5.5) will affect any mixes that use that component, regardless of what location the project is in.

The mix designs can also be used as a starting point to customize a mix design to your liking; each design can be copied, adjusted as you wish, and then saved with a unique product name.

The Concrete Mix Designs

So what is the difference between all the mix designs and how are they used in the IE4B? There are two main categories, Benchmark and EPD mixes, and in the IE4B we make a distinction between Database mixes and User Defined mixes. There are 6 database mixes that are included when the software is installed, ranging from 2500-8000 psi (15-55 MPa), and these are the concrete choices that are available in the assembly dialog boxes (as well as Extra Basic Materials). There are in fact 8 CRMCA benchmark mixes from 25-60 MPa, but only 5 of these and a 15 MPa proxy are available as radio button choices in the assembly dialog boxes, and all are available in Extra Basic Materials. These database mixes can be viewed (and copied if you wish to tweak the mix design) in the User Defined Concrete Mix Design Library by checking the “Include Database Products” at the top of the dialog box. All the rest are user defined mixes, which means they have to be loaded into the User Defined Concrete Mix Design Library.

If a project location is a Canadian city, then choosing a particular concrete strength using the radio buttons in the assembly dialog boxes will use the CRMCA benchmark for that strength in the model, and if the project location is an American city, then the NRMCA benchmark will be used.

The NRMCA Benchmark mixes, are average designs from each region and a national average design. There are 9 mixes per region, 6 with normal weight aggregates ranging from 2500-8000 psi compressive strength, and 3 with lightweight aggregates from 3000-5000 psi. The 6 national benchmark mixes with normal weight aggregates are the 6 database mixes included in the tool, and they are the same mixes that came from the v1 Benchmark report in 2014, and were available starting in v5.1 of the IE4B. Version 2 of the Benchmark report added 3 lightweight mixes to the national average and they have not been added to the database, they are available in an .AT4 file and can be loaded into users’ libraries. All 9 mixes in each of the 8 NRMCA regions are also available in their oThe NRMCA EPD mixes are not regionalized, but rather show different mix designs for each compressive strength range with varying proportions of Portland cement, slag cement, fly ash and aggregates. In each strength range, there are 8 mixes, and there are 9 strength ranges, 6 with normal weight aggregates and 3 with lightweight aggregates. All the EPD mixes are provided as user defined mixes and are available in their own .AT4 files.

The CRMCA mixes are organized a little differently, with 8 strength classifications from 25-60 MPa, with one benchmark mix and several EPD mixes per strength classification. The mixes are not regionalized, there are 8 “national” benchmark mixes, and 117 EPD mixes of various strengths, proportions of GU (Portland) or GUL (Portland Limestone) cement, slag cement, fly ash and aggregates. All the EPD mixes are provided as user defined mixes and are available in their own .AT4 files.

With this many mixes available, we’ve come up with a naming convention to help users sort through them all so they can just load the ones they need.

NRMCA

The EPD mixes are all labeled “Concrete NRMCA EPD” with a compressive strength and a fly ash and/or slag content. For example:

Concrete NRMCA EPD 2500-00-FA/SL |

a 2500 psi mix with 0% fly ash (FA) and slag cement (SL); i.e., 100% Portland cement based |

Concrete NRMCA EPD 3000-20-FA |

a 3000 psi mix with 20% fly ash |

Concrete NRMCA EPD 4000-30-SL |

a 4000 psi mix with 30% slag cement |

Concrete NRMCA EPD 6000-50-FA/SL |

a 6000 psi mix with a combined 50% fly ash and slag |

Concrete NRMCA EPD LW-4000-30-SL |

a lightweight aggregate (LW), 4000 psi mix with 30% slag |

There are 9 EPD mix .AT4 files, 6 normal weight mix designs from 2500 to 8000 psi and 3 lightweight mix designs from 3000 to 5000 psi:

NRMCA EPD Mixes - 2500 psi.AT4 |

NRMCA EPD Mixes - 3000 psi.AT4 |

NRMCA EPD Mixes - 4000 psi.AT4 |

NRMCA EPD Mixes - 5000 psi.AT4 |

NRMCA EPD Mixes - 6000 psi.AT4 |

NRMCA EPD Mixes - 8000 psi.AT4 |

The Benchmark mixes are all labeled “Concrete Benchmark”, with a region and a compressive strength. For example:

Concrete Benchmark South Eastern 2500 psi |

a 2500 psi mix for the South Eastern NRMCA region |

Concrete Benchmark North Central 3000 psi |

a 3000 psi for the North Central region |

Concrete Benchmark Eastern LW 5000 psi |

a lightweight (LW), 5000 psi mix for the Eastern region |

Concrete Benchmark 3000 psi |

a national average 3000 psi mix (database mix) |

Concrete Benchmark LW 4000 psi |

a national average 4000 psi lightweight mix (user defined mix) |

There are 9 benchmark mix .AT4 files, one for each region containing 9 mixes, 6 normal weight and 3 lightweight, and 1 file with 3 national average lightweight mixes (the other 6 are the database mixes already included in the tool):

Benchmark Mixes - NRMCA National Lightweight.AT4 |

Benchmark Mixes - NRMCA Eastern Region.AT4 |

Benchmark Mixes - NRMCA Great Lakes Midwest Region.AT4 |

Benchmark Mixes - NRMCA North Central Region.AT4 |

Benchmark Mixes - NRMCA Pacific Northwest Region.AT4 |

Benchmark Mixes - NRMCA Pacific Southwest Region.AT4 |

Benchmark Mixes - NRMCA Rocky Mountains Region.AT4 |

Benchmark Mixes - NRMCA South Central Region.AT4 |

Benchmark Mixes - NRMCA South Eastern Region.AT4 |

CRMCA

The EPD mixes are all labeled “Concrete CRMCA EPD” with a mix number (matching the mix numbers in the EPD), compressive strength, GU or GUL cement, with or without air entraining and a fly ash and/or slag content. It should be noted that although admixtures are included in the mixes in the LCA report, air entrainer and other admixture LCA data is not available in the IE4B and are therefore not included in these mixes. The LCA effects of admixtures is very small so not including them in IE4B will not affect the results to any appreciable degree. Here are some examples of the naming convention:

| Concrete CRMCA EPD Mix01 25-GU-air-00-FA/SL | Mix #1 from the EPD, a 25 MPa GU (Portland) cement mix with air entrainer, 0% fly ash (FA) and slag cement (SL); i.e., 100% GU cement based |

| Concrete CRMCA EPD Mix02 25-GU-00-FA/SL | Mix #2, the same as Mix 1 but without air entrainer |

| Concrete CRMCA EPD Mix27 30-GU-air-30-FA | Mix #27, 30 MPa, GU cement, with air entrainer, 30% flyash |

| Concrete CRMCA EPD Mix68 40-GUL-30-FA | Mix #68, 40MPa, GUL (Portland limestone) cement, without air entrainer, 30% flyash |

| Concrete CRMCA EPD Mix85 45-GU-35-SL | Mix #85, 45 MPa, GU cement, without air entrainer, 35% slag cement |

There are 16 EPD mix .AT4 files, 8 GU mix designs and 8 GUL mix designs, from 25-60 MPa:

| CRMCA EPD Mixes - 25 MPa GU.AT4 |

| CRMCA EPD Mixes - 30 MPa GU.AT4 |

| CRMCA EPD Mixes - 35 MPa GU.AT4 |

| CRMCA EPD Mixes - 40 MPa GU.AT4 |

| CRMCA EPD Mixes - 45 MPa GU.AT4 |

| CRMCA EPD Mixes - 50 MPa GU.AT4 |

| CRMCA EPD Mixes - 55 MPa GU.AT4 |

| CRMCA EPD Mixes - 60 MPa GU.AT4 |

| CRMCA EPD Mixes - 25 MPa GUL.AT4 |

| CRMCA EPD Mixes - 30 MPa GUL.AT4 |

| CRMCA EPD Mixes - 35 MPa GUL.AT4 |

| CRMCA EPD Mixes - 40 MPa GUL.AT4 |

| CRMCA EPD Mixes - 45 MPa GUL.AT4 |

| CRMCA EPD Mixes - 50 MPa GUL.AT4 |

| CRMCA EPD Mixes - 55 MPa GUL.AT4 |

| CRMCA EPD Mixes - 60 MPa GUL.AT4 |

There are no .AT4 files for the CRMCA benchmark mixes. Each strength class contains 1 benchmark mix (shaded in blue in the EPD), and those benchmarks are included in the database and are available when the tool is installed. They are:

| Mix# | Mix Name |

|---|---|

| 03 | Concrete Benchmark CAN 25 MPa |

| 22 | Concrete Benchmark CAN 30 MPa |

| 41 | Concrete Benchmark CAN 35 MPa |

| 60 | Concrete Benchmark CAN 40 MPa |

| 78 | Concrete Benchmark CAN 45 MPa |

| 89 | Concrete Benchmark CAN 50 MPa |

| 107 | Concrete Benchmark CAN 55 MPa |

| 117 | Concrete Benchmark CAN 60 MPa |

| Concrete Benchmark CAN 15 MPa |

The NRMCA EPD included a 2500 psi (15 MPa) benchmark mix, and the assembly dialog boxes have a 2500 psi (15 MPa) button, but the CRMCA’s EPD did not include a 15 MPa mix. Therefore, the mix design for “Concrete Benchmark CAN 15 MPa” is in fact the mix design from the NRMCA EPD and cannot be found in the CRMCA EPD report.

There are six radio buttons in each concrete assembly dialog box, and there are six NRMCA benchmark mixes but eight CRMCA benchmarks. The CRMCA 45, 50 and 60 MPa benchmarks are not available to choose from in the assembly dialogs, but they are included in the database. If you wish to use one of these benchmarks in your assembly, you can choose them as user defined products, but in order to do that, you must create them as user defined products. To do this, go to Tools> User Defined Concrete Mix Design Library, check the Include Database Products box at the top of the form, and the database products will appear in grey. Click the product you want, then click Duplicate, and a copy will be created.

We recommend you rename this duplicate so that you can distinguish it from the database version. This is now a User Defined copy of the database mix and will be available in the User Defined drop down box of each concrete assembly form.

All mixes, database and user defined are available in Extra Basic Materials.

How to Load Mix Designs into Your Library

It’s quite simple, after closing this dialog box, choose the benchmark and/or EPD .AT4 file(s) that apply to your region or compressive strength that you want to load and click Open. The file(s) will open as projects in the project tree, and you will see a project conversion report. This report is just telling you that there are new materials in those projects that you do not have in your library, and that they have been added. Go to Tools > User Defined Concrete Mix Design Library and you should see the mix designs you chose to add to the library. If you do not want all of the mixes from a particular file, you can click on any one design and then click Remove and it will be deleted. And you’re done, those mixes will be available to use in your project modelling and will remain in your library until you remove them. Close the library dialog and then you can close the project file(s) in the tree. You only need to open any one bulk mix design file once to load the mixes into your library, after that the project files will be of little use to you.

What to Do with Existing Projects That Use v1 NRMCA Mix Designs

If you have previously loaded the 48 NRMCA EPD mix designs from the v5.1 of the IE4B and use them in projects, don’t fret, you can still use them. Those 48 mix designs are exactly the same as the v5.2 mix designs that are discussed here, only the name has changed.

So for example, the old “NRMCA EPD 2500-00-FA/SL” mix is now called “Concrete NRMCA EPD 2500-00-FA/SL”, but the components are exactly the same. The LCA results will change from IE4B v5.1 to v5.2 because the LCA data has changed for some of the component materials (e.g., cement), but the mix designs are the same.

You can keep any old user defined mixes that you have in your library, if you import any of the new ones, they will simply be added to the library. A problem only occurs if you try to load a new mix design with the same name as an existing one.

If you want to change the concretes in old projects to the newly imported concrete mixes, the only way to do that is to open each concrete assembly and change the concrete in the User Defined dropdown box, or in extra basic materials, you have to enter the new concrete as a new material and delete the old.

Can You Delete the Old Mix Designs From Your Library?

Yes you can. If you want to clear out your library of the 48 EPD mix designs, and only load a few of the new mixes, you can, in fact we recommend it. The 48 EPD mixes create a long list lo look at when choosing a user defined concrete and it’s easy to choose the wrong one when the names are so similar, so reducing the clutter in your library is a good thing if you only expect ever to use a few of the mixes. This is the reason we’ve separated the mix design files into groups of nine mixes because no one is ever going to need access to all 150 mix designs.

If you have a project that used one of the old mixes, even if you delete that mix from your library, the mix design is saved in that project file, so the next time you open it, the mix design will be loaded back into your library, and you can go on using it.